FORMATION DAMAGE

EVALUATE AND SELECT THE RIGHT DRILLING AND COMPLETION FLUIDS FOR YOUR WELL. AND, WHEN THINGS DON’T WORK OUT AS PLANNED, ENHANCE WELL PRODUCTIVITY THROUGH EXPERT INVESTIGATION AND REMEDIATION OF FORMATION DAMAGE.

Our Formation Damage Group at PREMIER COREX uses world-leading facilities to evaluate performance and identify issues in all kinds of wells. We utilise high-temperature and pressure coreflood simulators with representative core, materials, and all relevant fluids to compare and rank operational fluids. Conclusions and recommendations are augmented by our use of innovative interpretative analyses. As independent experts, our impartial advice is used globally to assist in finding potential or existing problems, evaluate operational fluids and hardware, and improve hydrocarbon recovery. Our global services have centres of excellence that simulate well operations at various stages or cumulatively through drilling, clean-up, completion, workover, treatment, and remedial/contingency treatment.

OUR SERVICES:

• Reservoir characterisation: including reservoir properties and mineralogy, particle size distribution, rock mechanics, and fines migration

• Wellbore operations: “Return permeability” to evaluate drilling, completion, frac, diverter, water shut-off & other fluids

• Clean-up/treatment fluid assessment: e.g. displacement Fluids, spacers, breakers, biocides, dissolvers, clay stabilizers

• Matrix stimulation fluid assessment: including strong acid (HCl/HF), alkali, and all other fluid types

• Acid frac

• Hydraulic frac Fluid

• Proppant and gravel pack

• Scaling: prediction/modelling, dynamic & static incubation, dynamic tube blocking, Formation Damage corefloods, inhibitor desorption corefloods

• Inhibitor evaluations: compatibility under dynamic, static and multiphase flow evaluations of inhibitors including scale, asphaltene, wax, corrosion

• Water compatibility and quality for injection, re-injection or disposal: Solids filtration, oil removal, scaling potential, mixing of source waters/PWRI, fines migration during injection, water compatibility (including clay swelling), emulsion, sludge, or wax formation

• Carbon capture and storage assessments: Carbon Dioxide injection for storage performance re compatibility for successful injection within the formation

• Sand and solids control hardware assessment: PSD, rock mechanics, flowrate dependency, sand retention testing (including low to high pressure with solids), with evaluations including screens, proppant, and gravel pack

• Microbial damage: including incubation studies, coreflood microbial assessments, and souring & biocide evaluations

• Tertiary recovery compatibility in EOR treatments (EOR/MEOR): compatibility around the injection/production wellbore area and deeper into the matrix

• Shale sensitivity: including incubation at temperature and evaluation of swelling

• Gas storage & carbon capture: to evaluate compatibility between the reservoir what is being injected for storage. Ability to handle carbon dioxide in gas and dense phases.

• Interpretative analysis: utilising techniques including XRD, thin section, scanning electron microscopy (SEM), cryogenic SEM, CT scanning, and micro/nano-CT scanning

• Diagnostics of wellbore alteration: Innovative techniques (3D Alteration Models) and numerical simulation of impairment

• Consultancy: Data mining, review of existing data, troubleshooting, recommendations on focus areas & studies

• Training: Formation Damage & Improved Hydrocarbon Recovery training courses

We have been consultants for independent formation damage assessments since 1985, which means that we have gained vast experience and an excellent reputation with operators around the world. Our huge database of results allows us to make meaningful comparisons and put study results in context. Through use of our novel research and developments, we have received both innovation and technology awards, as well as “focused recognition” awards from clients.

PREMIER COREX Formation Damage Group in Aberdeen, Houston, Oklahoma and Abu Dhabi perform core flood simulations or compatibility tests to better understand wellbore operational performance. The effects of chemicals and fluids throughout well operations are evaluated to determine alteration(s) at any stage that may affect well inflow.

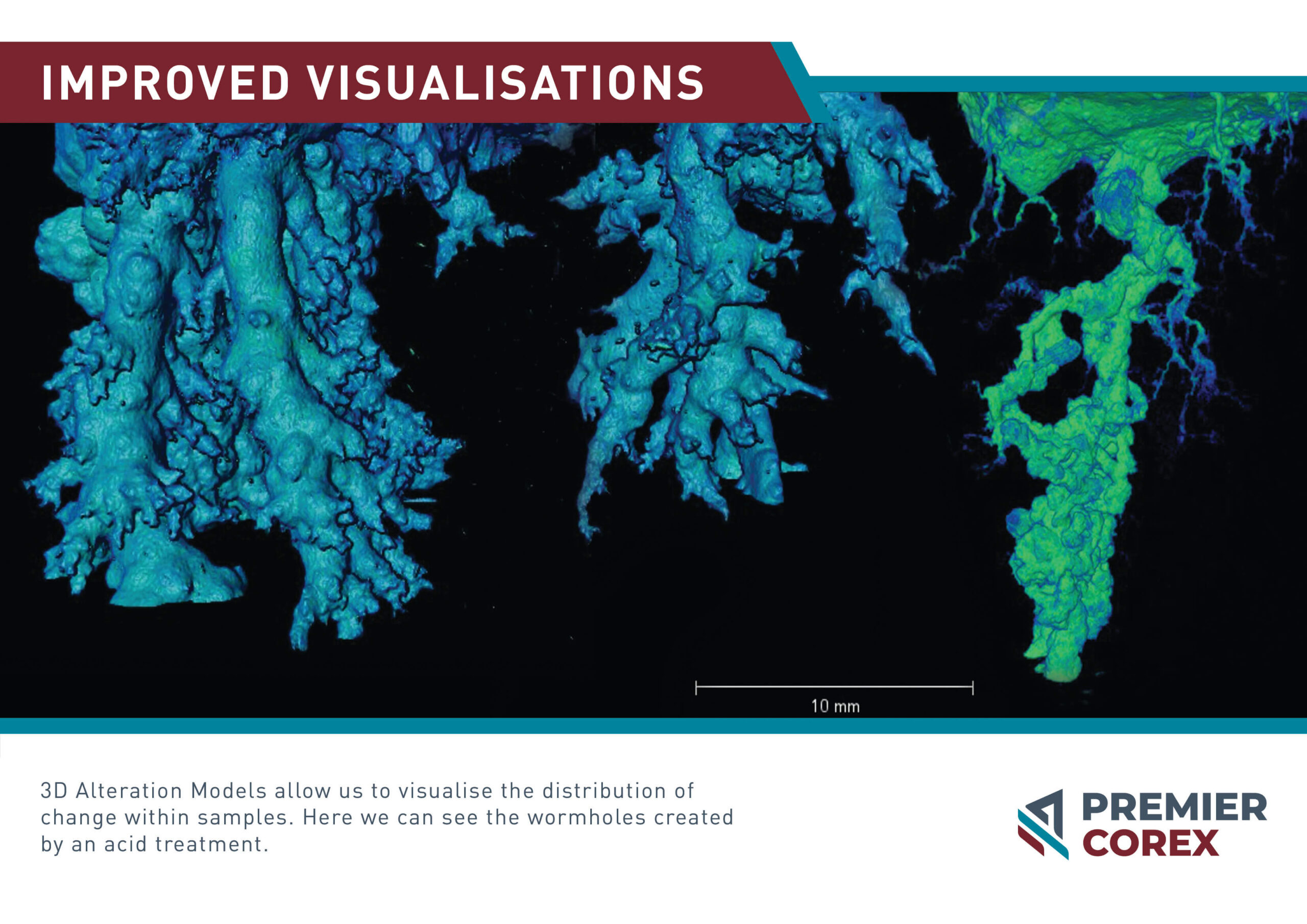

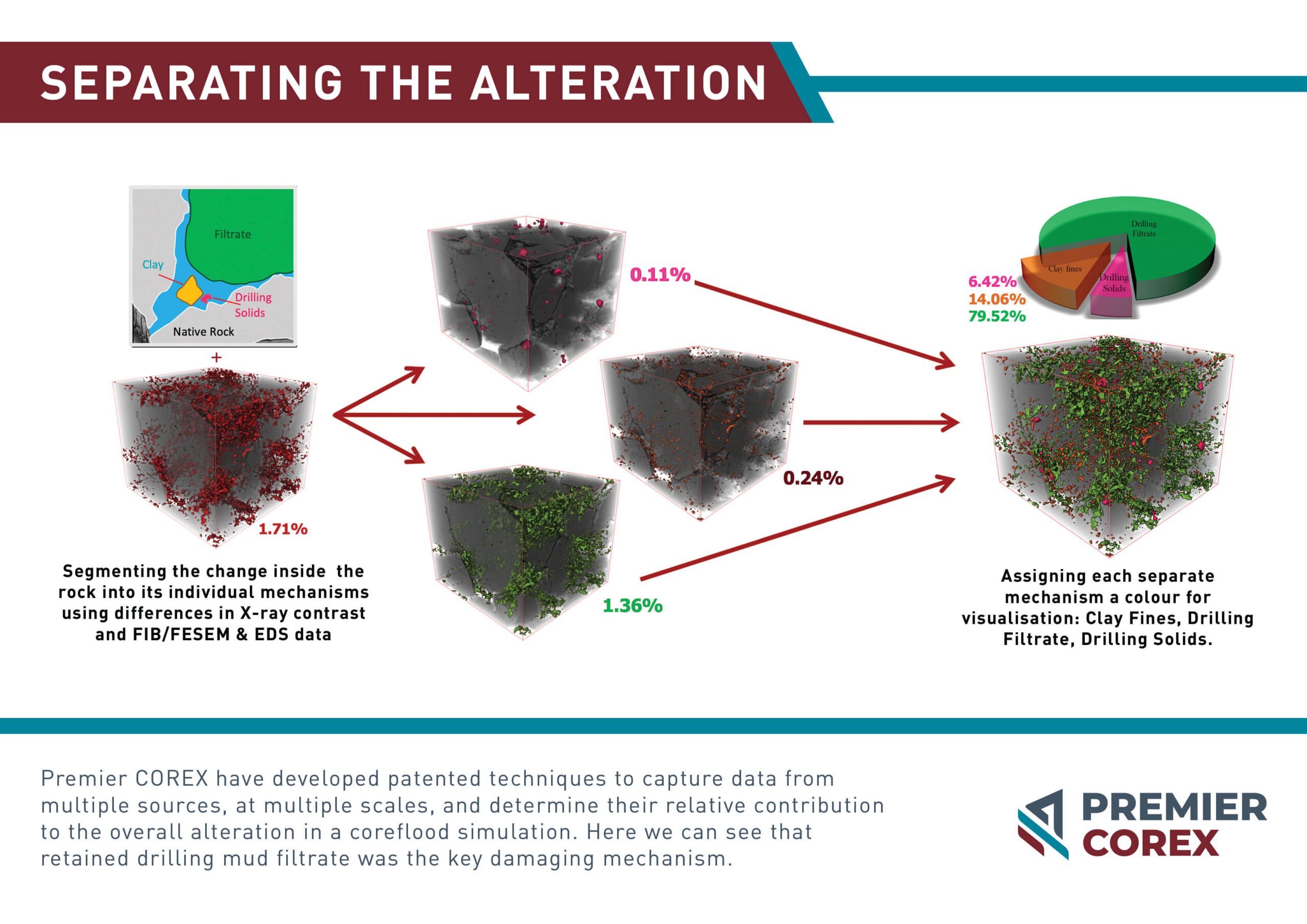

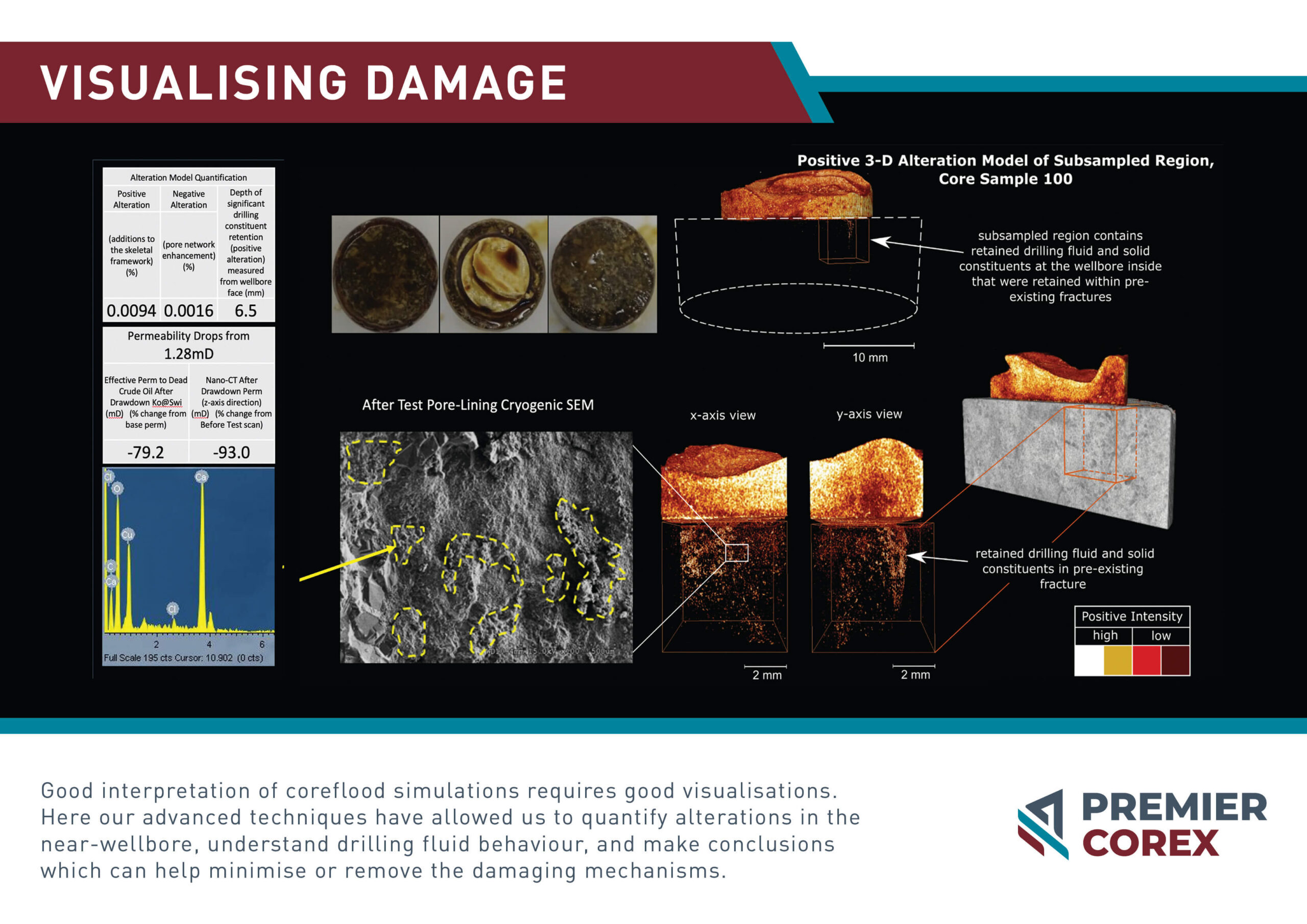

Compatibility is investigated for co-mingling fluids from topside to downhole as well as rock-fluid interactions are investigated at wellbore conditions to mitigate field risk. By using representative core samples and relevant wellbore hardware/fluids (e.g. screens, drilling fluids, completion fluids, clean-up fluids, displacement fluids, treatment fluids, kill pills, Lost-circulation material pills, healer pills, breaker fluids, strong or weak acids, workover fluids), improvements in well operations can be realised and hardware/fluid candidates can be ranked on their performance. Our Nano CT scanning provides 3-dimensional alteration models and alongside our specialist geological techniques we can quantify and identify the distribution and nature of mechanisms which may alter the near wellbore at any stage of operations. Our investigative process can improve hydrocarbon recovery by identifying issues so that specific actions can be taken (preventative or remedial), ensuring well inflow expectations are met.

PREMIER COREX also investigate water injection/disposal compatibility to assist operators by performing advanced coreflood simulations under near-wellbore conditions. PREMIER COREX have vast experience and expertise in sampling and characterizing water samples. Poor quality water can cause impairment, which restricts flow and reduces injection rates. By simulating injection into the reservoir rock and using modelling software, we are able to assess injection performance for operators.

PREMIER COREX uses industry leading bespoke simulators and has experts in geological interpretation and analysis with over 35 years’ experience. Our approach to understanding issues is based upon us asking the questions “what, where, and why?” and answering them using a range of techniques:

• Core flood simulation data to tell us what and when something has happened in terms of how much permeability alteration, as well as additional information such as who’s product and how much filtrate loss volumes and drawdown/production data to aid interpretation

• Micro/Nano-CT scanning to show us where how much and what were alterations and their locations within the core samples. As part of this process we can use our patented techniques to quantify the positive and negative change alongside the overall change within a core sample.

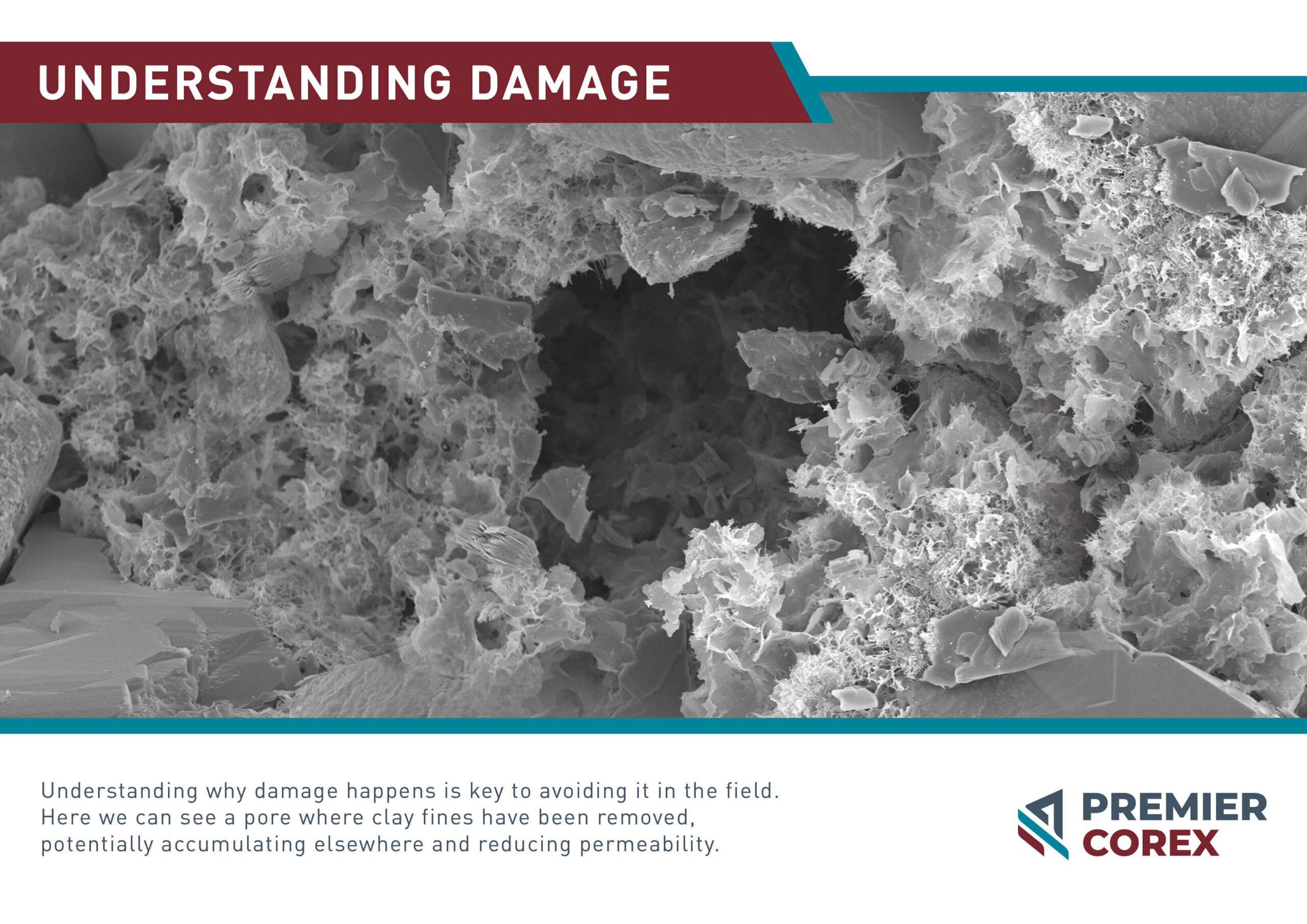

• Geological analysis to “zoom in” at high resolution to the changes identified by the Micro/Nano-CT scans and help us understand why and how there have been changes and what to do for improvements.

Key Results

• Quantification of permeability from coreflood simulations at representative wellbore conditions

• Understanding what could (or has) happened in the field: knowing what the problem is allows specific solutions to be identified

• Identification and assessment of potential remediation methods

• Independent assessment and performance ranking to select the most beneficial completions hardware or operational fluid sequence

IMPROVE YOUR HYDROCARBON RECOVERY WITH ACCURATE WELLBORE SIMULATIONS AND EXPERT DIAGNOSIS

VIEW OUR OTHER SERVICES